Product Tooling & Materials

TANIQ has extensive expertise on materials and product testing, tools, mandrels, flanges and couplings.

Reinforcement materials - Cord / Fabric

TANIQ has extensive experience with a wide range of reinforcement materials and their properties. Replacing conventional reinforcement material (sheet/fabric and metal wires) with individual cords is required to use TANIQ's technology. Therefore, a standard part of product optimisation is finding the best cords for your products' performance, behaviour and rubber-to-cord adhesion. Continues research is performed on load-absorption, stress-resistance, abrasion-resistance, performance degradation by vulcanisation, structural behaviour and adhesion and coatings.

Rubbers

The large variety of applications for TANIQ's technology demands for compatibility with various rubber compounds. TANIQ's technology uses rubber strip winding to enable accurate, efficient and fast automation. Therefore, changing from rubber sheets in the conventional manual process to strips is required. Changing to a different rubber compound or supplier is however NOT required. TANIQ's technology is developed to incorporate your material and material expertise with libraries in the design software. Moreover, the rubber tools for automated rubber winding have been designed for maximum compatibility - as long as the rubber is supplied in strips.

Flanges and couplings

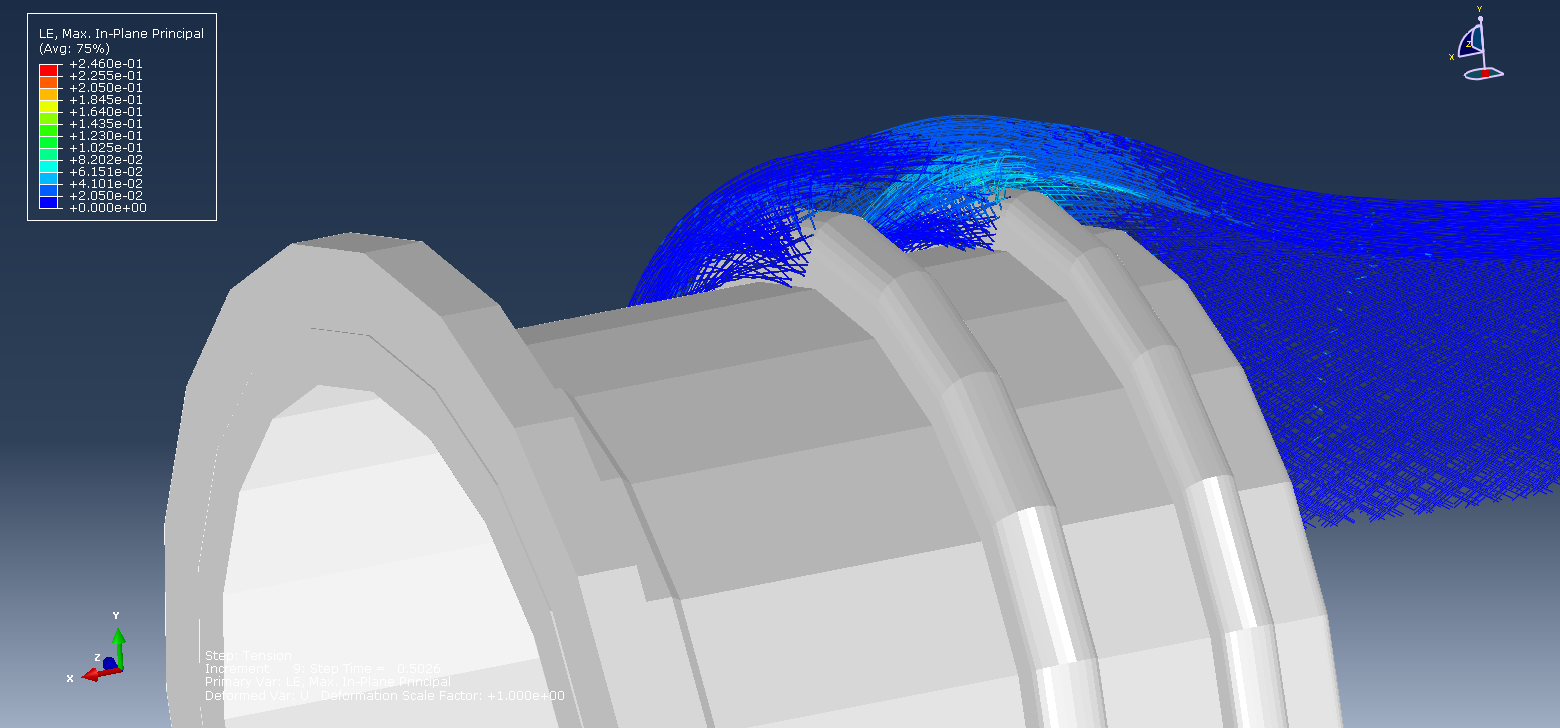

TANIQ has developed new solutions to integrate flanges and couplings in your products more efficiently. The main principle is that the flanges and coupling are integrated in the product body by continuous winding with cords. Conventional processes mostly involve manual folding of fabric sheets to form the flange or coupling connection. Sometimes also metal wires are added to keep the folded structure in place. TANIQ's technology uses the tensile strength in the cords to make more efficient connections and even create self-sealing effects. The flanges and couplings have been successfully applied in pipe-plugs, air springs, large diameter hoses, pinch valve sleeves and lifting bags.

Smart mandrels and tooling

TANIQ has more than 8 years of experience with building prototypes and developing production processes. As a result TANIQ has developed many product mandrels and tooling. The choice for the mandrel and tooling concept strongly depends on the required number of prototypes or products you want to build with it. TANIQ has experience with disposable mandrels for one-time use, aluminium or composite mandrels and tooling for making small series and robust steel mandrels for series productions. Besides costs and lifetime of the mandrel and tooling, also the handling time (assembly and de-assembly) is an important selection criteria.

Prototype testing

As a result of the extensive development of reinforced rubber products, TANIQ has many years of experience with prototyping and testing. Typical tests that are executed are: burst pressure tests at different restricted build-in lengths, measurement of radial and axial deformations at different pressures, axial and lateral dynamic testing and force-stroke measurements (for actuators). TANIQ has testing facilities in Rotterdam for doing basic testing. In addition, the FEA Toolbox enables accurate products analysis and product testing. Furthermore, most manufacturers test their prototypes at their own test equipment to benchmark the results against their other products.