Cord Reinforcement Technology

The foundation behind TANIQ's solutions for reinforced rubber products

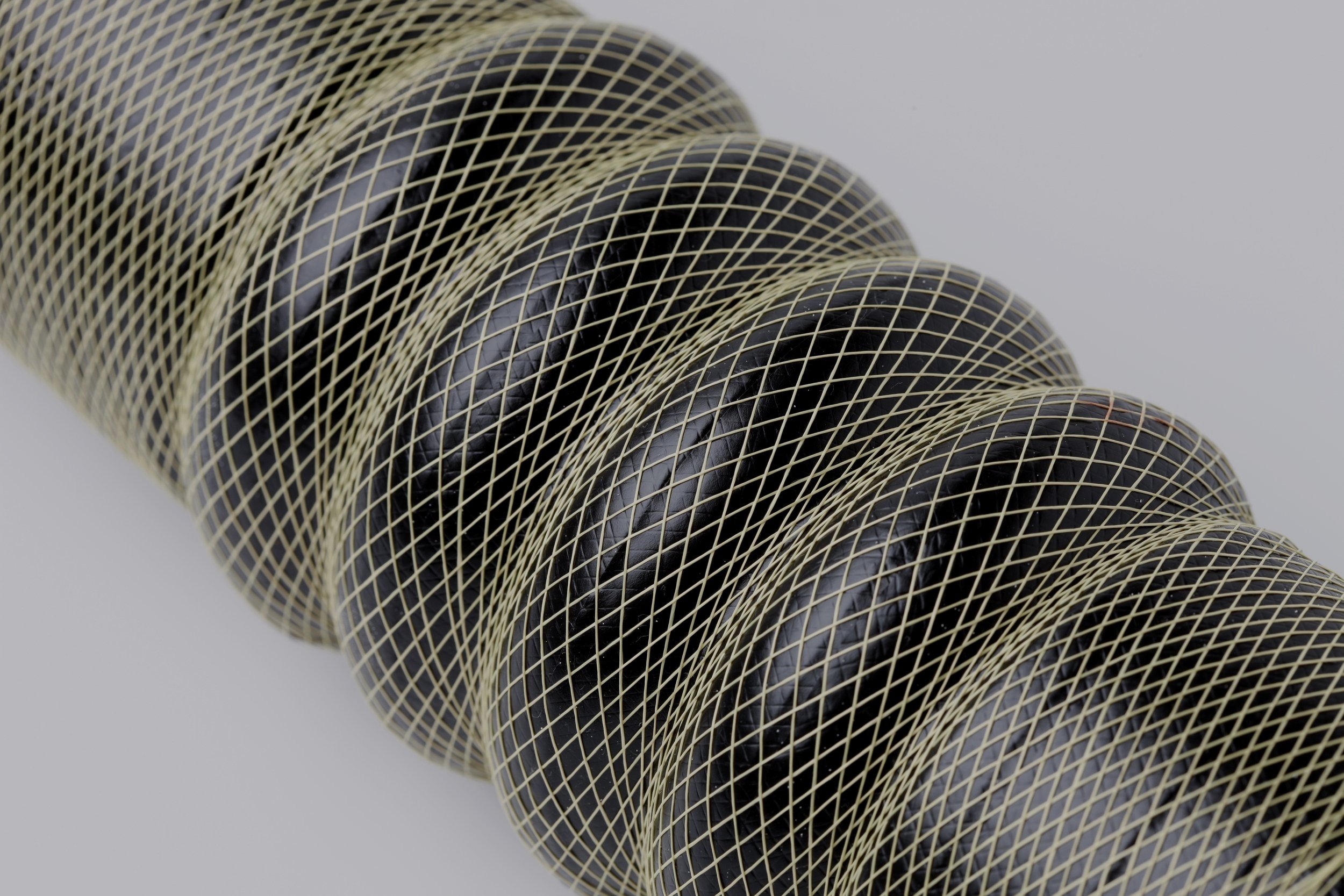

Optimizing the reinforcement structure of rubber products

TANIQ is specialized in the design of cord reinforcement structures for rubber products. For optimal reinforcement of (rubber) products TANIQ uses design principles for lightweight engineering from the Aerospace industry (TANIQ is a spin-off from Aerospace Faculty of Delft University of Technology). TANIQ strives to optimize the use of the cords by calculating their optimal path trajectories (e.g. geodesic path) and accurately placing them on those trajectories using industrial robots.

Multi-layer reinforcement optimisation and modelling

TANIQ has developed mathematical and FEA models to optimize multi-layer reinforcement structures for rubber products. One of the main challenges of multi-layer reinforcement structures is to efficiently load all layers. This challenge becomes even bigger for stiff reinforcement materials like aramids. Optimization can be obtained by applying the right cord winding angles. With manual application of fabric sheet, accurate control of the winding angles is not possible. However, with the robotic winding process, the cords can be accurately placed on the predetermined angles. Multilayer optimisation and layer activation has been intergrated in TANIQ's software to realize optimum loading of the cords in the actual product.

Rubber-to-cord adhesion research

A good adhesion between rubber layers and reinforcement layers is beneficial for the product performance during dynamic behavior. Different types of cords are used in reinforced rubber products such as aramid, nylon and polyester. Each having their own advantages. The cords are treated with a special coating (e.g. RFL) to improve the adhesion between the cords and the rubber. TANIQ works closely together with Teijin Aramid and Milliken to develop the optimal cord construction and obtain maximum adhesion between the cords and rubber.