Robot Systems

Robotic winding systems for automated manufacturing of rubber products and components

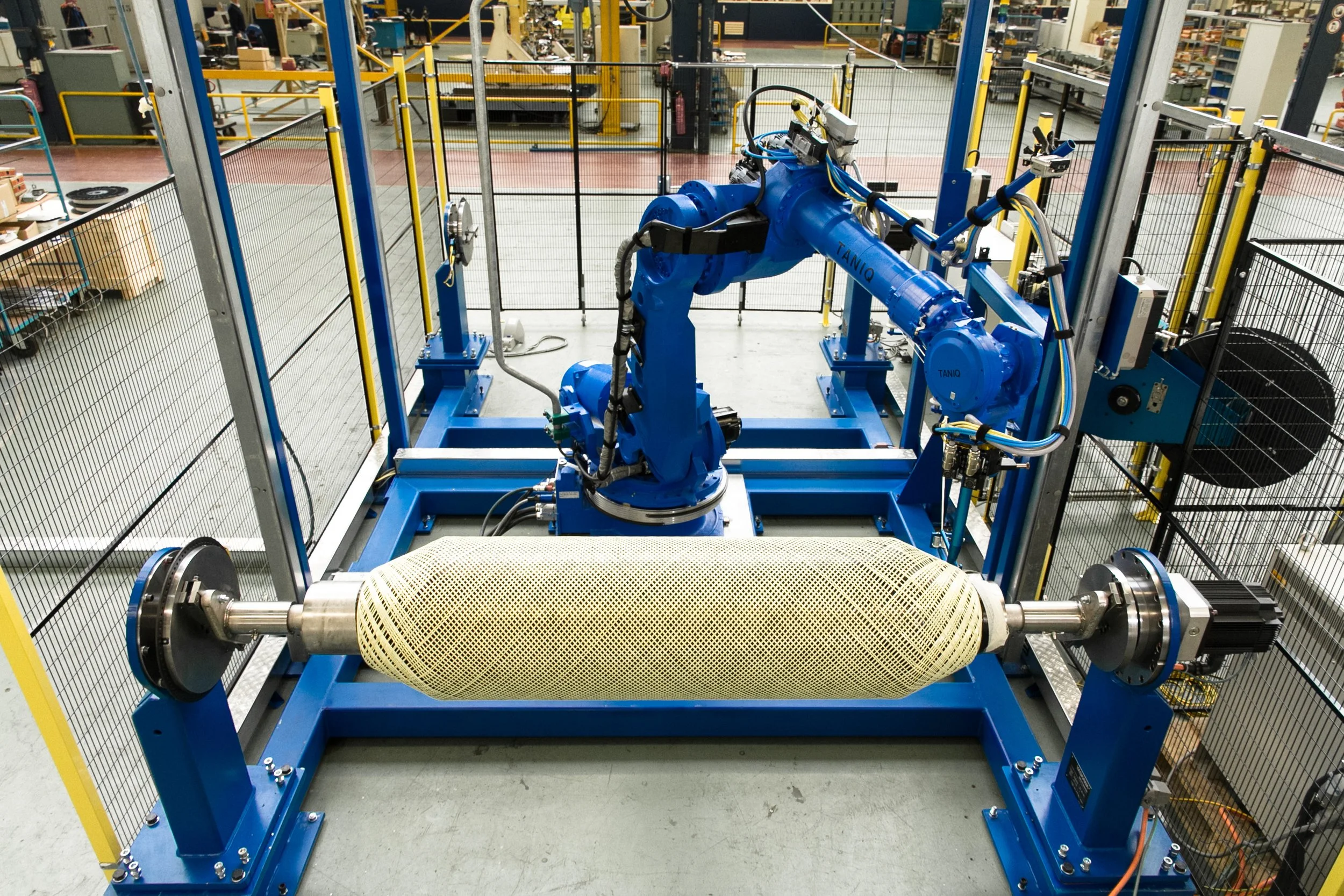

As one of the first companies worldwide to develop a robotic filament winding system in 2007, TANIQ is a true pioneer in this field. By developing a large variety of customized winding systems for the rubber and composite industry, TANIQ has developed unique expertise. Our experience ranges from developing robotic systems for winding 350k automotive hoses per year, to developing heavy-duty winding equipment for dredging hoses of 12m long and 1m diameter, with a mandrel weight of 20.000kg. Together with our Clients, we develop customized robotic winding systems providing flexible and cost-efficient solutions for their automation challenges.

TANIQ has supplied robotic winding systems, under the brand name Scorpo, for manufacturing of hoses, pipe-plugs, rubber expansion joints, pipes, pressure vessels and many other products. The most common lay-out of a robotic winding system comprises a manipulator for rotating the product and a robotic arm which can pick-up different end-effectors for material application. Depending on the product dimensions two ‘standard’ systems are defined, being i) the Scorpo Virgo for medium sized products and ii) Scorpo Taurus for large sized products.

TANIQ has developed custom end-effectors for application of a large variety of materials, such as fibers, cords, rubber strips, tapes, metal wires and labels.

Scorpo systems overview & customisation

To automate the production of reinforced rubber products, TANIQ has developed the Scorpo Robotic system platform. Research and developments has resulted in a reliable automation solution for various applications. A large variation of products can be manufactured with a single robotic system that is capable of automated placement of rubber, reinforcement material and wrapping tape. The overall design and operation of the robotic systems is identical from one robot cell to the other. However, because of the specific expertise and specialisms of different manufacturers in the industry, the systems can be customised per application and customer. Or completely custom systems can be developed. An overview of the robot cell layout and customisation options is provided.

Scorpo VIRGO system for medium size products

To automate the production of reinforced rubber products of medium product size, TANIQ has developed the Scorpo Virgo. The Scorpo Virgo is suitable to manufacture products up to approximately 3000mm length and 1500mm diameter. The Scorpo Virgo is used for manufacturing of pipe-plugs, expansion joints and lifting bags, and is also suitable for products of comparable dimensions such as inflatable packers, pinch valve sleeves, air-springs and more.

The system has been designed to be customised and optimised per customer. If customisation is required and to what degree depends on the customers situation, for example, the product types, size range, design and facility.

Scorpo TAURUS system for Large hoses

To automate the production of reinforced rubber products of medium product size, TANIQ has developed the Scorpo Virgo. The Scorpo Virgo is suitable to manufacture products up to approximately 3000mm length and 1500mm diameter. The Scorpo Virgo is used for manufacturing of pipe-plugs, expansion joints and lifting bags, and is also suitable for products of comparable dimensions such as inflatable packers, pinch valve sleeves, air-springs and more.

The system has been designed to be customised and optimised per customer. If customisation is required and to what degree depends on the customers situation, for example, the product types, size range, design and facility.

Scorpo Robotic FAQs

Robotic automation provided by TANIQ is unique in the rubber industry. The automation processes and product designs are distinctly different form conventional products. To answer frequently asked questions and provide an understanding of the basics of the Scorpo Robotic automation setups, the FAQ are covered.