FEA Toolbox - Rubber

Finite Element Analysis (FEA) for reinforced rubber products

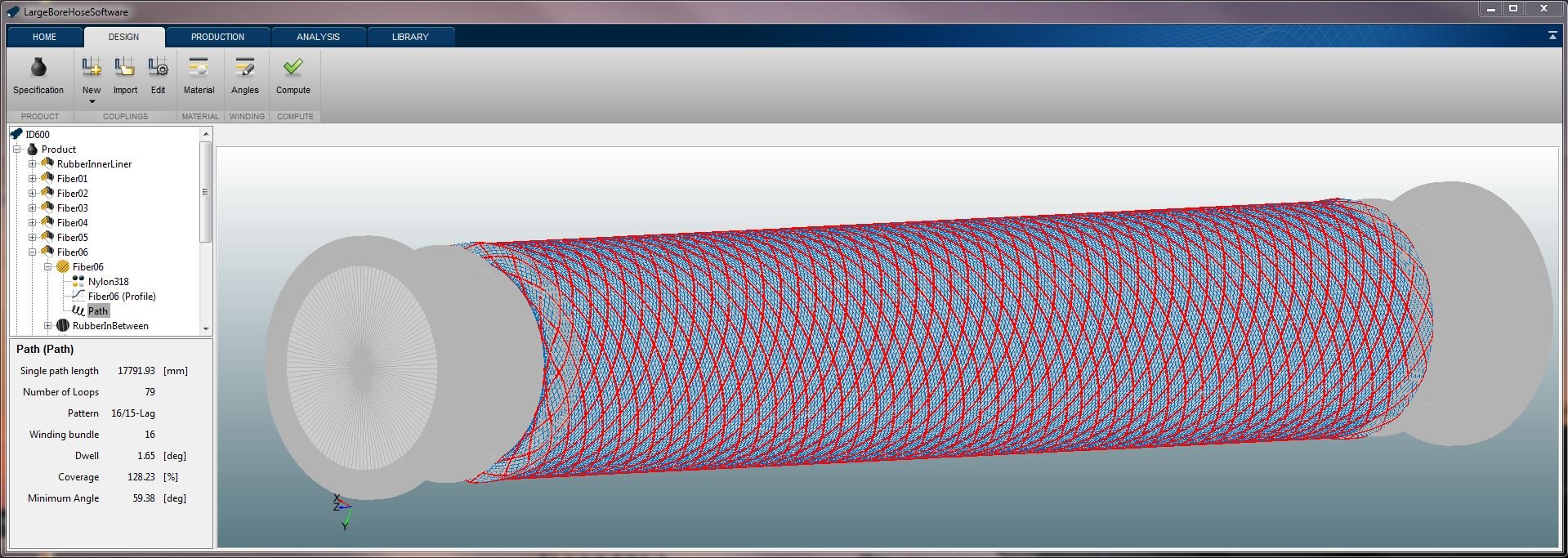

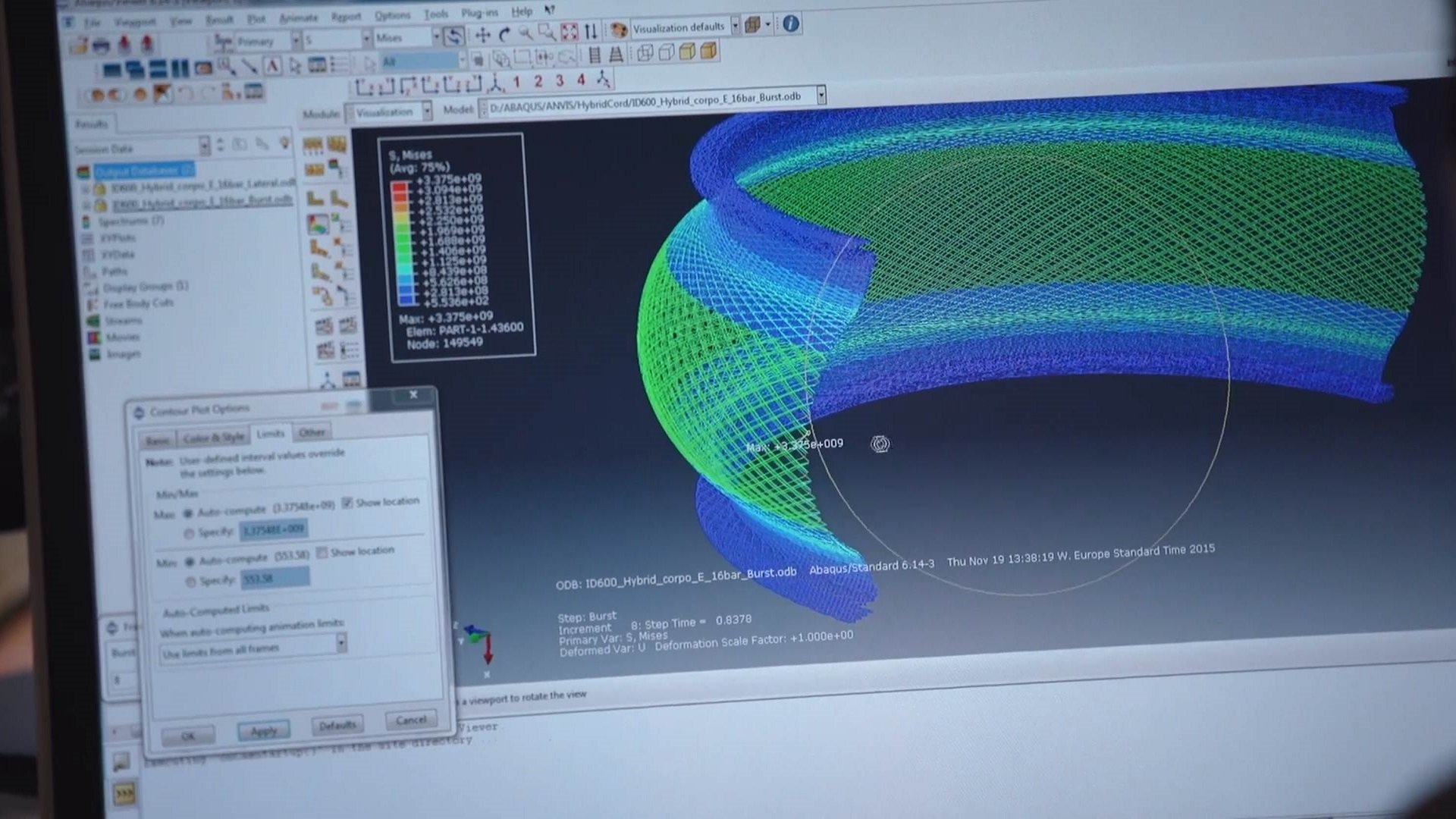

TANIQ's Technology enables Finite Element Analysis with the exact geometry of the designed products. This is achieved through a direct coupling of the design made with the Design Software and commercial FEA Software such as Abaqus, using TANIQ’s FEA Toolbox. To complete the circle, the exact same design is also uploaded to the robotic equipment for production, such that the final product matches the product design and the FEA model. The obtained consistency between design, FEA model and final product is truly unique for mandrel-built reinforced rubber products.

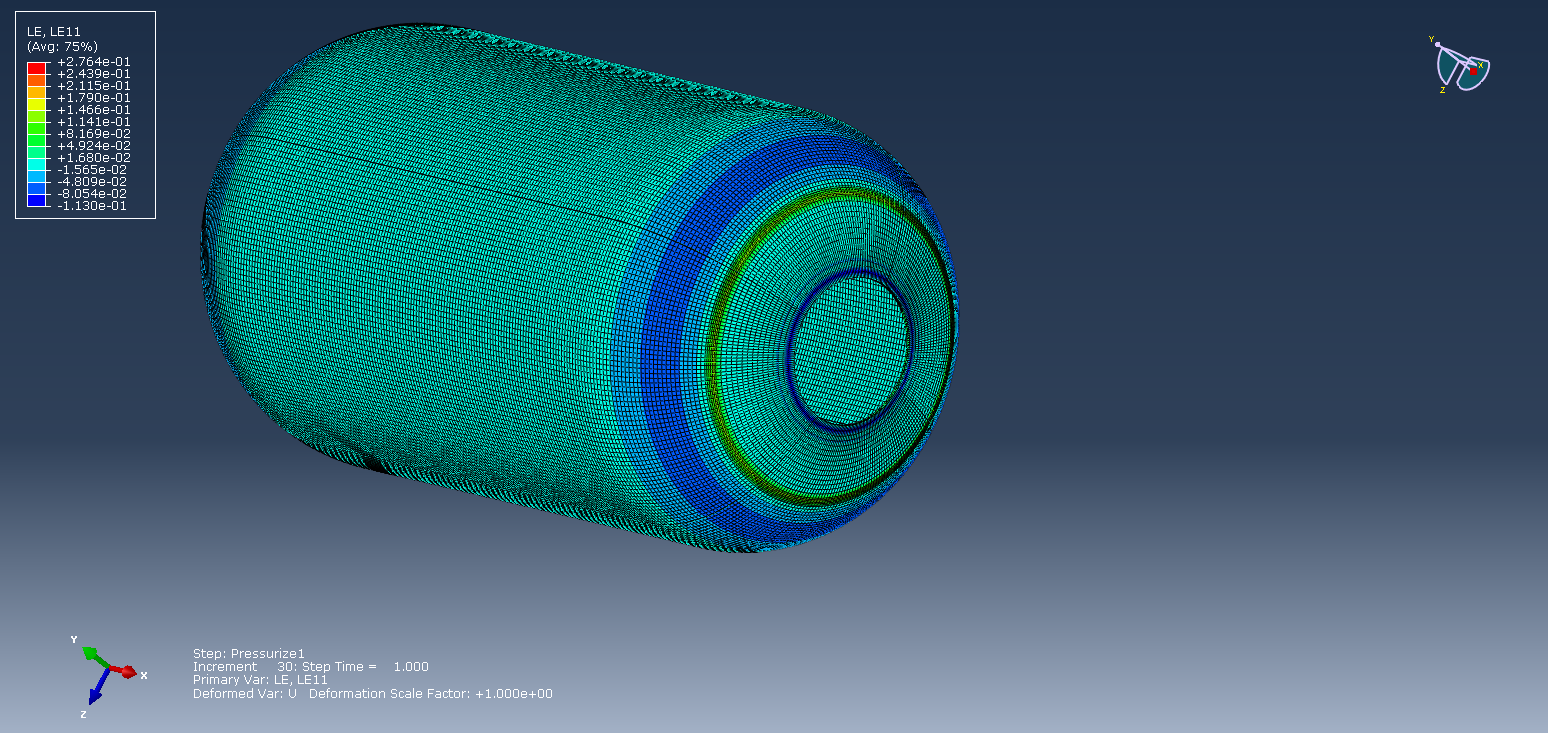

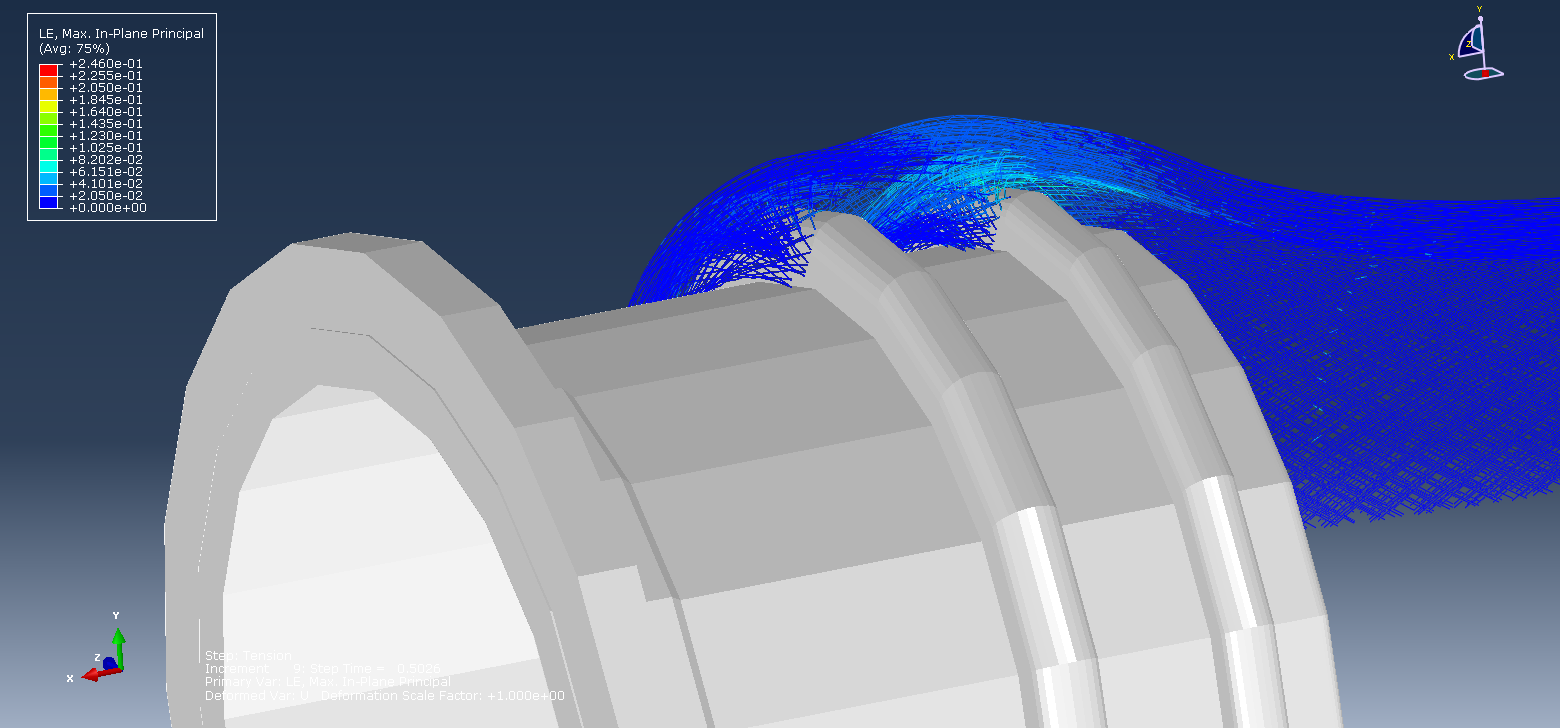

Using TANIQ’s FEA Toolbox analysis of individual fibres and their interaction with the rubber elements is possible. Significant R&D was done on material model definitions, and interaction between different material elements. The high quality of the model representing the final product makes it possible to make accurate predictions of product performance for different load cases. The FEA can be used for analysing product behaviour (e.g. burst failure, maximum movements, etc.) and for comparison of design alternatives without building and testing of prototypes. Using FEA instead of, or before developing and testing of prototypes saves significant R&D costs. Ultimately, this creates new possibilities to improve your product performance and quality. An additional benefit is that you can automatically create accurate and reliable FEA-reports.

Simulate your product performance and optimise the design using Finite Element Analysis

First a design is made with the Design Software and exported to the FEA Toolbox. In the FEA Toolbox the user can define load cases and generate input files for Abaqus. Typical results are:

Burst pressure prediction (maximum fibre tensile strength)

Analysis of (local) stress concentrations

Stiffness responses/ load displacement curves

Failure mode prediction

Maximum movement capacity (axial compression/elongation, lateral deformation)

Reinforced rubber product FEA: Case Studies

As an example of the application and the possibilities of the FEA Toolbox, two case studies are presented.

Case study I: Rubber Expansion Joint for pipe-systems

Rubber expansion joints are used in piping systems to compensate for pipe movements and vibrations. As a pipe-system engineer you want to know the load displacement characteristics to predict the maximum allowable axial and lateral movements. If your pipe-system exceeds the maximum allowable movement of the expansion joint the system could fail. Therefore, being able to accurately predict the expansion joint behavior is critical for the safety of the system. With this FEA model TANIQ has developed a dynamic model that enables to simulate the expansion joint performance under different load cases. For example, expansion joints are not subject to a constant pressure, but will be exposed to variating pressures which will lead to variating stiffness behavior. Therefore, in the simulation we have analyzed the expansion joint stiffness at different pressures and plotted the force-dispacement curves. Besides providing a more accurate prediction of the expansion joint behavior under different load cases, the FEA model is used to optimize rubber expansion joint designs. Simulation of design changes in the FEA model gives insight in the various design options, and enables to significantly reduce the amount of physical prototyping which saves costs and time.