The Shift to Robotics in Filament Winding and Composite Manufacturing

While the industry has long been relying on traditional CNC filament winding methods, the emergence of robotics in the past few decades has transformed manufacturers’ approach to composite production. In this blog post, we dive into the pioneering application of robots by industry-leading companies who seek to constantly innovate composite manufacturing technology.

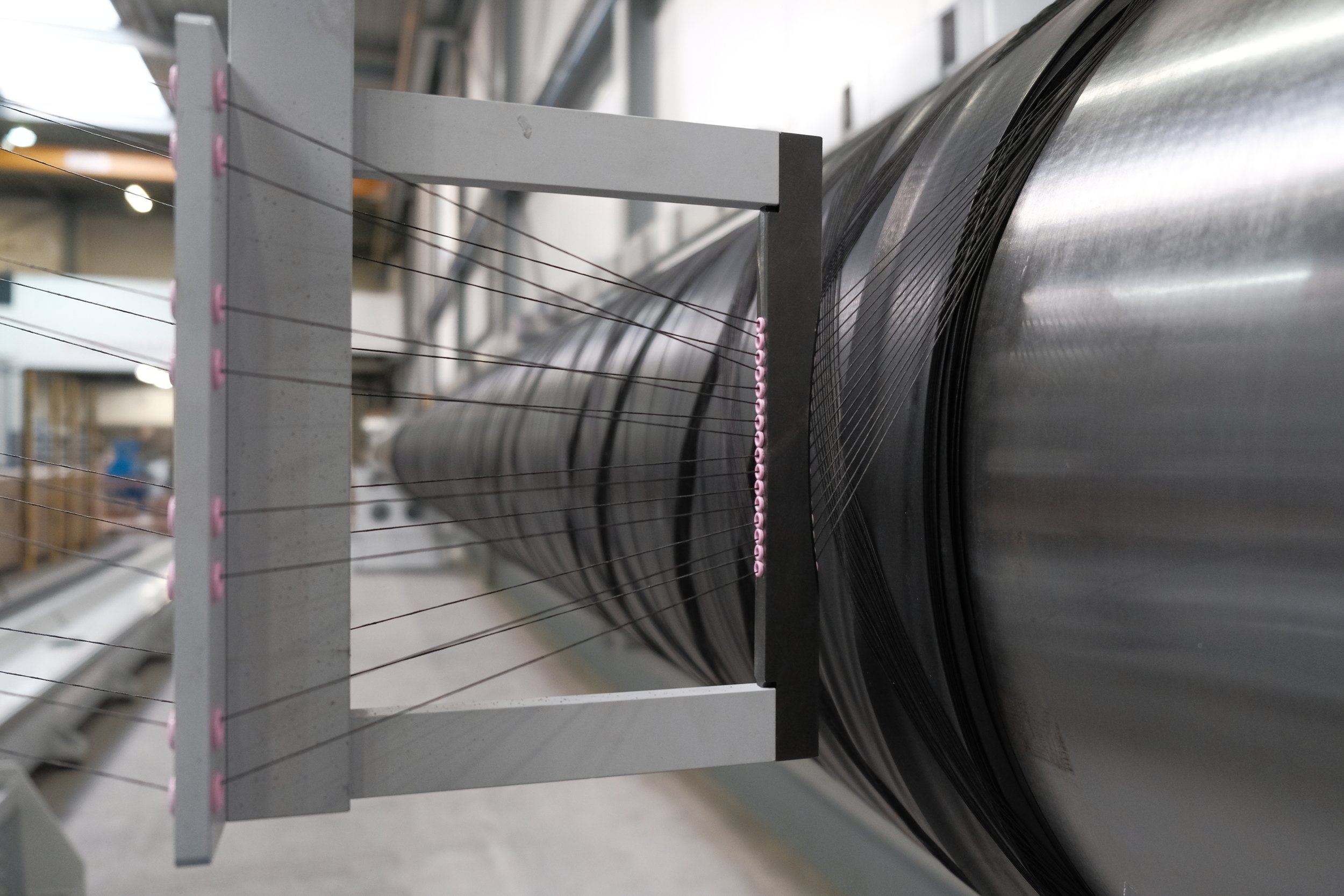

Traditional CNC Filament Winding

Conventionally, filament winding is carried out on 2-5 axis CNC equipment. During this process, resin impregnated fibers are wound on a rotating mandrel while kept under tension. To boost machine capacity, multiple spindles carrying a mandrel can be wound simultaneously.

Although such methods have been the foundation for many applications in the composite industry, the need for further automation and process integration has increased, leading to advanced innovations in composite manufacturing.

Robotic Techniques Emerging

Around 2005, pioneering companies like MF Tech, followed by TANIQ in 2007, started using industrial robots for filament winding. These robotic arms having 6 degrees of freedom, enable more accurate material deposition on complicated mandrel contours, and allow for optimization of speed profiles by using the entire 3D winding envelope. A great advantage is that the robots can be equipped with various material application tools, which they can automatically switch between from a tool changer station. Such adaptability and versatility allow the robots to combine multiple material deposition processes, like filament winding, tape placement, and 3D printing, all in a single hybrid system. Additionally, these robots can handle pre-production tasks like mandrel loading and post-production tasks such as grinding or drilling.

Hybrid Robotic Systems

A combined solution of automated patch application and towpreg winding (Image courtesy of Cevotec)

Such advancements are not only theories. Many enterprises from various tech industries have applied this robotic filament winding technique in their specific niches, resulting in significant improvements in their processes.

In the field of Carbon Overwrapped Pressure Vessels (COPVs) for Hydrogen storage, several companies and research organizations are developing hybrid design and manufacturing solutions. An example is the robotic application of local reinforcement patches in the dome areas, in combination with towpreg winding, to reduce carbon material consumption in COPVs by Cevotec (Germany). In the 3D printing sector, CEAD, a robotic 3D printing company in the Netherlands, adds continuous fibers to the printed layers to achieve (thermal) stability in their large-size 3D printed parts. In the rubber composite industry, TANIQ (Netherlands) has developed robotic winding systems that can apply rubber material in combination with continuous cord winding, which are then vulcanized together forming a reinforced rubber composite part. All of these companies found robotics as a solution for improving efficiency, precision, and product performance.

A combination of 3D printing and thermoplastic tape laying (Image courtesy of CEAD)

A combination of rubber strip placement and cord winding (image courtesy of TANIQ)

Advanced Software and Control

The increasing complexity of hybrid robotic systems requires more advanced, sophisticated, and powerful software to program and control them. Besides the more general tool-changing operations, the different processes and their process parameters need to be controlled accurately. This has resulted in the development of more powerful CAD/CAM software allowing users to customize individual process parameters per layer, and even per section of the product/mandrel profile. This grants users maximum control over parameters like layer thickness, winding tension, or laser intensity throughout different sections of the product.

Following, new software solutions are emerging providing more advanced control over such integrated process parameters. Within 3D printing, most robot programs are created using a ‘slicer software’ like Cura to create G-Code, which 3-5 axis CNC winding program can then be converted into a robot program using software like RoboDK, wherein process parameters can be further defined in a robot post-processor. For composite winding and placement processes, TANIQ has released their TaniqWind Pro CAD/CAM software, the only software having a dedicated robotic post-processor, with advanced options for controlling process variables throughout each layer and section in the product.

Conclusion

In summary, for mass-producing composite parts like rods, tubes, and pressure vessels, CNC equipment with multiple spindles is still preferred. However, robotic systems, once mainly used for R&D for many years, are now increasingly utilized for more complicated and niche applications, and for more automated hybrid production systems combining various tasks and material application processes.