Rubber Winding & Placement Tools

Robot tools for automated rubber winding of reinforced rubber products

Special Rubber Winding Tools have been developed for automated winding of rubber. TANIQ's technology uses rubber strip winding to enable accurate, efficient and fast automation. The rubber strip is wound on spools which are loaded on the tool using quick connectors. The rubber tools are compatible with all commonly used high consistency rubber compounds (e.g. NR, CR, EPDM, SBR, etc.). The tools can be used with various rubber thickness and strip widths.

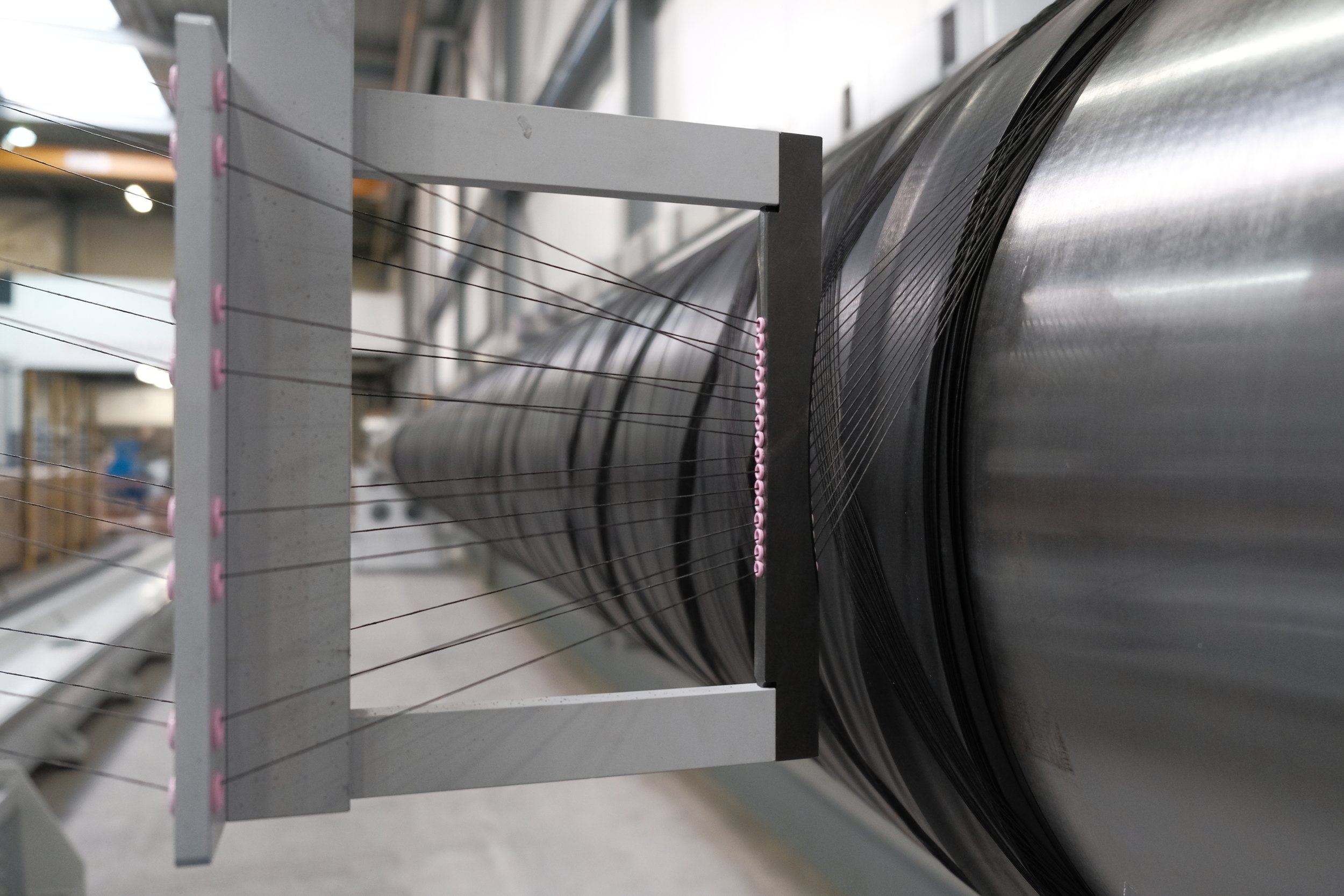

Rubber Winding Process

TANIQ's robotic rubber winding process has been developed to automate the winding of rubber layers in reinforced rubber products. Typically reinforced rubber products contain an inner rubber liner, a rubber outer cover and sometimes in-between rubber layers. Using robotic winding, such rubber layers can be wound very accurate, and at high speed. Furthermore, automated winding results in good consistency and reliability.

TANIQ has done extensive R&D in the field of automated winding of unvulcanized rubber strips. The unvulcanized rubber has low 'green strength' which requires advanced control systems to obtain the required rubber strip dimensions and tolerances during winding. Furthermore, these systems have to work also at high speeds and accelerations. Therefore, TANIQ has developed Rubber Winding Tools and rubber winding algorithms. TANIQ's rubber winding process is suitable for all commonly used high consistency rubber compounds (e.g. NR, CR, EPDM, SBR, etc.).

An important factor in the functions of the system, is the link between the different components of TANIQ's robotic automation setups. The design software uses parametric input to calculate the rubber layers of the product. The design software will generate a production file that coordinates the robot to manufacture this exact product. In combination with the advanced functions of the rubber tool, the product's rubber layers are manufactured exactly (1:1) as designed.

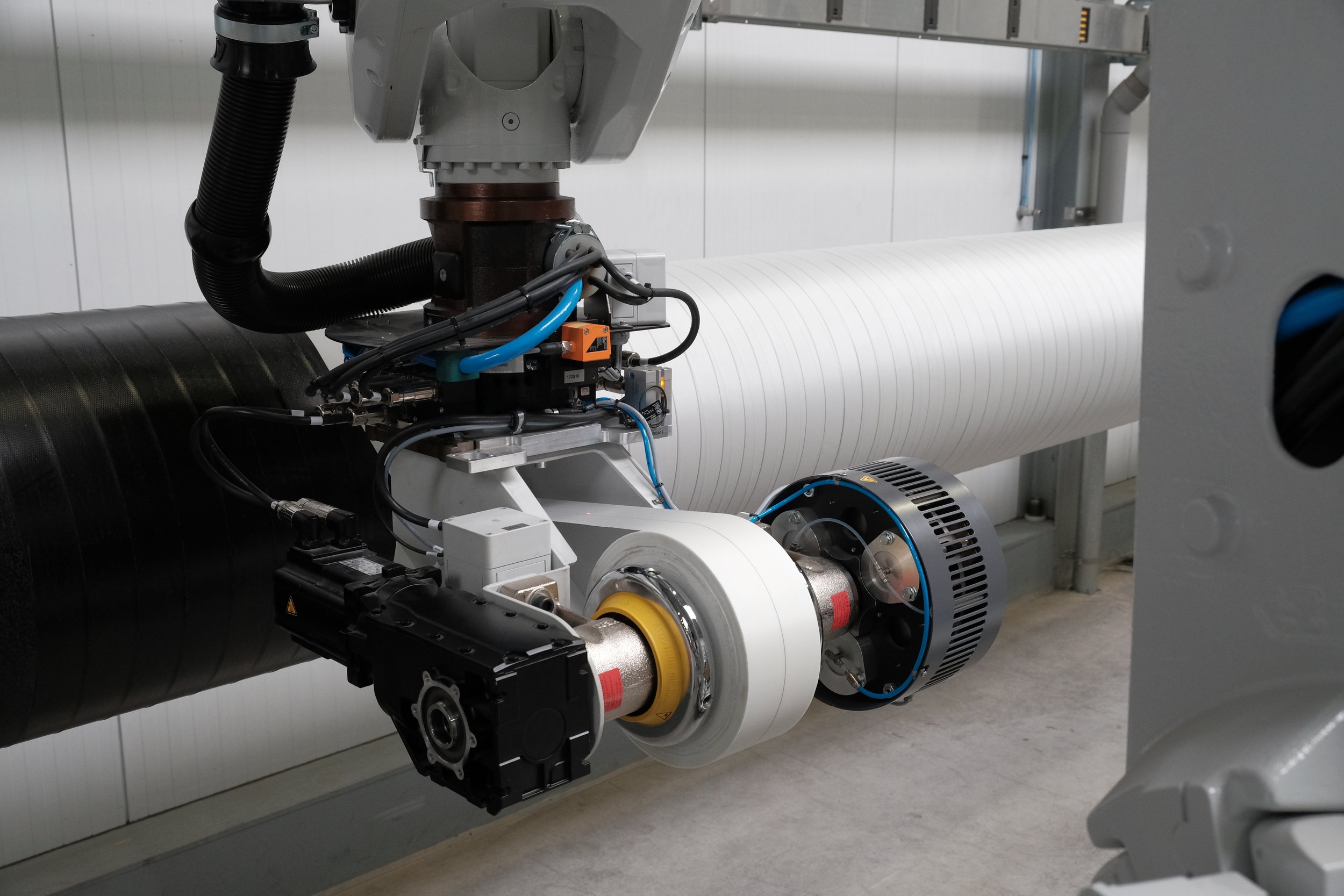

Rubber Winding Tools

The rubber winding tool is the system attached to the end of the robot arm, which enables the winding of rubber strips. The rubber winding tool holds the spool of rubber strip, guides the strip to the product, pulls the plastic backing foil from the strip, and keeps the strip at the required dimensions (width and thickness) during winding. The rubber winding tools can be designed in different configurations and sizes depending on the process requirements. Its main functionalities are:

Feeding and control of rubber strip;

Automatically stopping the process when rubber finishes;

Break detection of rubber and backing tape strip + ability to continue the production from that point;

Spooling and easy release of backing tape from tool;

Easy changing of rubber spool with smart connector;

Be able to see the process online and change settings/parameters remotely.

Recently, TANIQ has implemented systems for automated attaching and cutting of the rubber strip. These functionalities enable to start and stop rubber winding processes without intervention of the robot operator. As a result, the operator is not bound to be near the robot during rubber winding, so he can to do other tasks. The robotic system can even be programmed to pick up a second rubber tool in case the first rubber spool empties during a winding process. With these systems the following functionalities are added:

Automatically attaching of rubber strip to mandrel/product;

Automatically cutting of rubber strips.

Currently TANIQ provides two standardised tools with customisation options. For the medium Scorpo set-up, the rubber tool is designed for rubber spools with up to 25 kg of rubber. The tool can be used with various strip widths, ranging from 40 to 80 mm. As a result of the tool's design and functions, it is suitable for a large variety of rubber types.

Suited for spools with maximum diameter of 600mm;

The rubber tool is suitable for a maximum of 25 kilo rubber;

Tape width between 40-80 mm;

Tape thickness between 0.5-2 mm;