TaniqWind Design

TaniqWind Design - powerful design software for composites

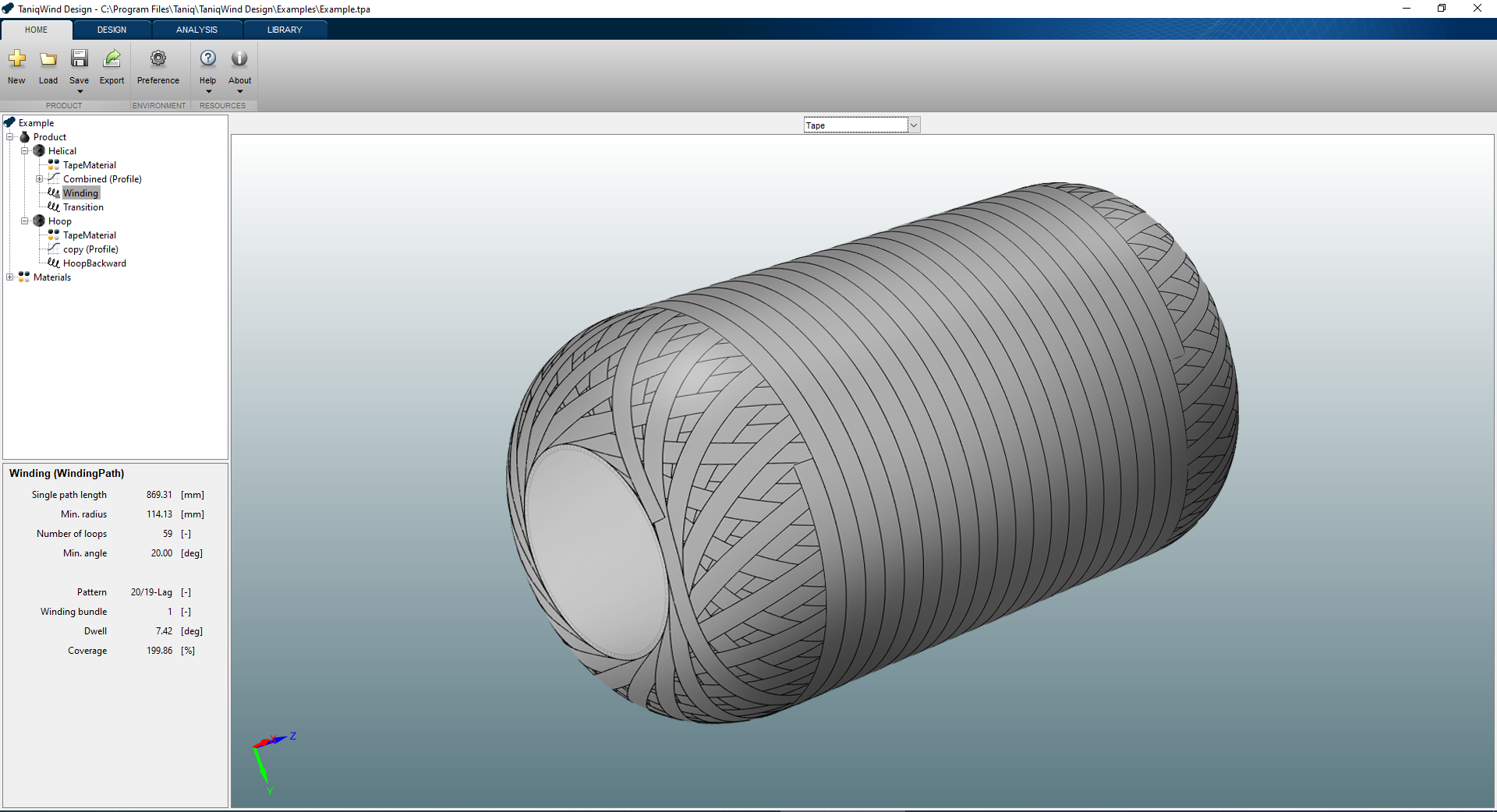

TANIQWind Design is a powerful software for design of filament wound composite parts such as pipes and pressure vessels. TaniqWind Design can be used for making composite pressure vessel designs based on (wet) filament winding, towpreg winding and winding/placement of thermoplastic tapes. This version does not have a Manufacturing Module for generation of winding programs. For the full Design and Manufacturing solution, discover TaniqWind Pro.

Key Features:

Mandrel generation (continuous profile)

Mandrel data import feature (incl. DXF)

Pipes and axis symmetrical mandrel geometries

Winding path & pattern generator

Geodesic and non-geodesic winding paths

Constant in-planar curvature paths

Circumferential (hoop) winding

Helical winding

Transition layer winding

Coverage path

Segmented path option for designing advanced winding paths

Winding path and pattern simulation

Short introduction video to TaniqWind Design

The video gives a short introduction to making a pressure vessel in TaniqWind Design (helical layer, transition layer and hoop layer) and exporting the design to Altair HyperWorks.

Highlighted features

1. Continuous Mandrel Profile Description

TaniqWind uses a novel approach to describe the mandrel profile, providing a continuous representation of the mandrel surface. This improved profile definition does away with discretizing the profile surface in individual sections, describing it instead as a continuous (analytical) surface – thereby increasing the accuracy of the winding path calculations and therefore the Finite Element model.

Improved profile description as continuous analytical surface

Increased accuracy of winding path calculations

More accurate and reliable FE results

2. Coverage path algorithm

The coverage path algorithm automatically searches for a tape path corresponding to the requested coverage. This is achieved by automatically changing several parameters within a given bandwidth such as i) winding angle, ii) polar opening, iii) friction and iv) dwell. This functionality is especially useful for designing pressure vessels whereby a 200% coverage per layer is required, without having gaps or overlap between adjacent tapes.

Software automatically searches for a tape path trajectory for the requested coverage within specified bandwidth of the following criteria:

Angle

Polar opening

Friction

Dwell

3. Improved buildup calculation for fibers and tapes

TaniqWind includes a powerful build-up prediction functionality for filaments and tapes. TANIQ has developed sophisticated mathematical models to predict buildup behavior and has validated them in winding trials. The improved buildup calculation provides accurate results of actual buildup behavior during manufacturing, drastically improving consistency between the Finite Element model, and the final product.

Advanced mathematical models to represent the build-up behavior

Optimized for critical product regions such as domes and polar openings for pressure vessels

Accurate match of actual build-up behavior during manufacturing

High consistency between the design, FEA model and the final product

4. Custom data structure export to Altair HyperWorks

TaniqWind has an integrated functionality to export design data to Altair Hyperworks, which enables the automatic generation of an accurate Finite Element model of the design. Due to the specific data structure developed in collaboration with Altair, unique details and information of the winding structure are included in the output towards Altair HyperWorks, resulting in more highly representative outcome.

Generate data file for FE models automatically

Specific format developed in collaboration with Altair

Unique structure and information included in export file

Resulting in a more representative model

5. Constant in-plane curvature paths

The constant in-plane curvature functionality enables the creation of tape path trajectories using the maximum allowable in-plane curvature as the criteria for defining possible path trajectories. This functionality is especially useful for tape placement processes whereby path trajectories are not defined by friction but are restricted by the maximum allowable in-plane curvature of the tape.

More information

TaniqWind Design has been released at the JEC Paris 2022. Contact TANIQ for more information or a demonstration of the software. A license for the software can be ordered at TANIQ. Furthermore, TaniqWind Design will be available for registered users of the Altair Partner Alliance Platform.