Customer Interviews

Customer Interviews

In these customer interview series we talk with our Clients about how they experience working with TANIQ.

Interview with John Custers, CEO of Lansas

Lansas develops and supplies high quality pipe-plugs and packer systems. In 2013 Lansas started their first development with TANIQ, which lead to an optimized plug design, automatically manufactured on robotic equipment. In this interview John Custers, CEO of Lansas, shares his experience on working with TANIQ .

Interview with Steve McAlister, Board Member of Sepro Systems

Sepro Systems is Canada’s largest supplier of mineral processing and aggregate equipment with offices worldwide. In this interview Steve McAlister, Board Member of Sepro Systems, tells more about his experience with working with TANIQ on the design of their new invention: a peristaltic pump hose having a nonsymmetric cross-section requiring 50% less sealing force.

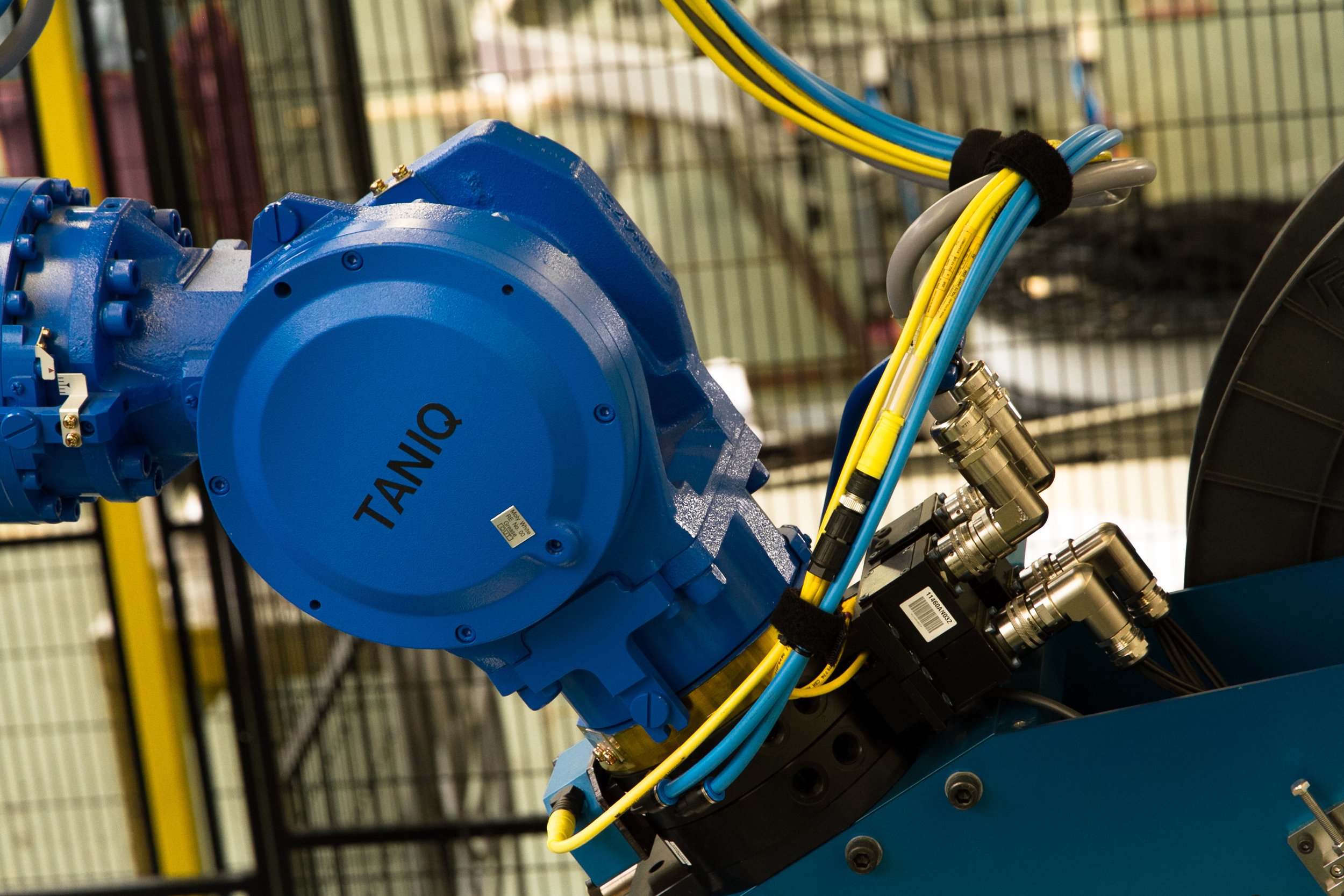

Interview with Ed van Breugel, Technical Authority Filament Winding from GKN Fokker Aerostructures

GKN Fokker, part of GKN Aerospace, has selected TANIQ as a technology partner for developing and supplying a robot-assisted filament winding machine and powerful winding software. GKN Fokker and TANIQ have closely collaborated to develop a dedicated filament winding system capable of meeting GKN Fokker’s requirements for manufacturing and developing advanced wound composite parts.

Interview with Enrico Gennasio, Alfagomma CEO Europe and The Americas

Alfagomma is a global leading company in the field of design, manufacturing and distribution of hydraulic and industrial fluid handling systems. In this interview Mr. Enrico Gennasio, CEO Europe and The Americas, tells more about his experience with working with TANIQ on automation of the design and manufacturing of high-end rubber expansion joints for marine and naval industries.