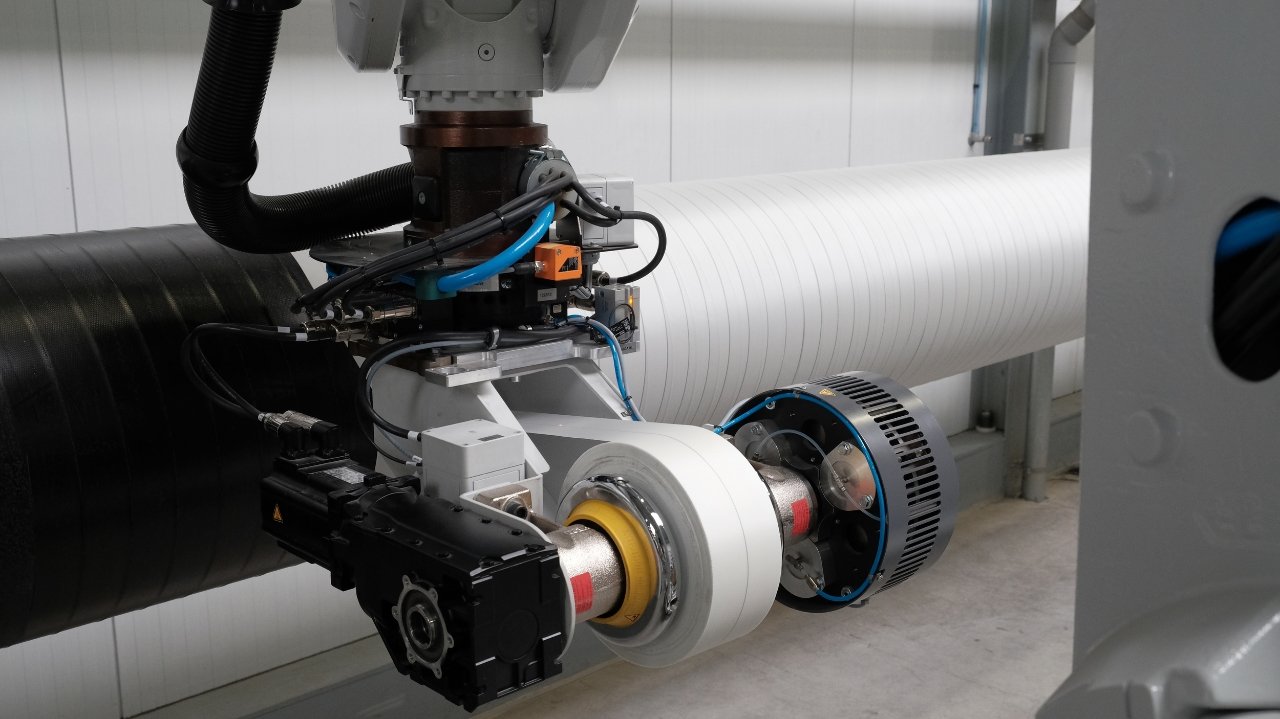

Robotic Production Simulation

Realtime robotic simulation

To preview the robotic winding processes TANIQ simulates the processes using software such as MotoSIM and Robot Studio. In these programs you can load 3D CAD files of the actual robot, robot tools and mandrel. Furthermore, you can enter all settings for your robot, mandrel rotator and mandrel itself (e.g. rotation speeds, accelerations, moments of inertia). Next you can load the actual winding programs to simulate the winding process. With all the correct settings the simulation will be representative for the actual winding process and production times. TANIQ uses this simulation to optimize the configurations of the robot cells, for reachability studies and to check for collisions between robot and mandrel.

Winding simulations - reachability & windabilty

After making a product design with the design software TANIQ can simulate the winding process using Motosim software. This enables to simulate the actual winding process in a digital environment to analyze windability and reachability. The windability simulation is to analyze a possible collisions between the winding tool and product. The reachability simulation is to determine if the robot can actually reach all product extremities (e.g. for large complex shapes). The advantage of this software is that it enables to optimize the winding programs without the need for physical testing on the robot.