Robotic Winding

Robotic winding processes

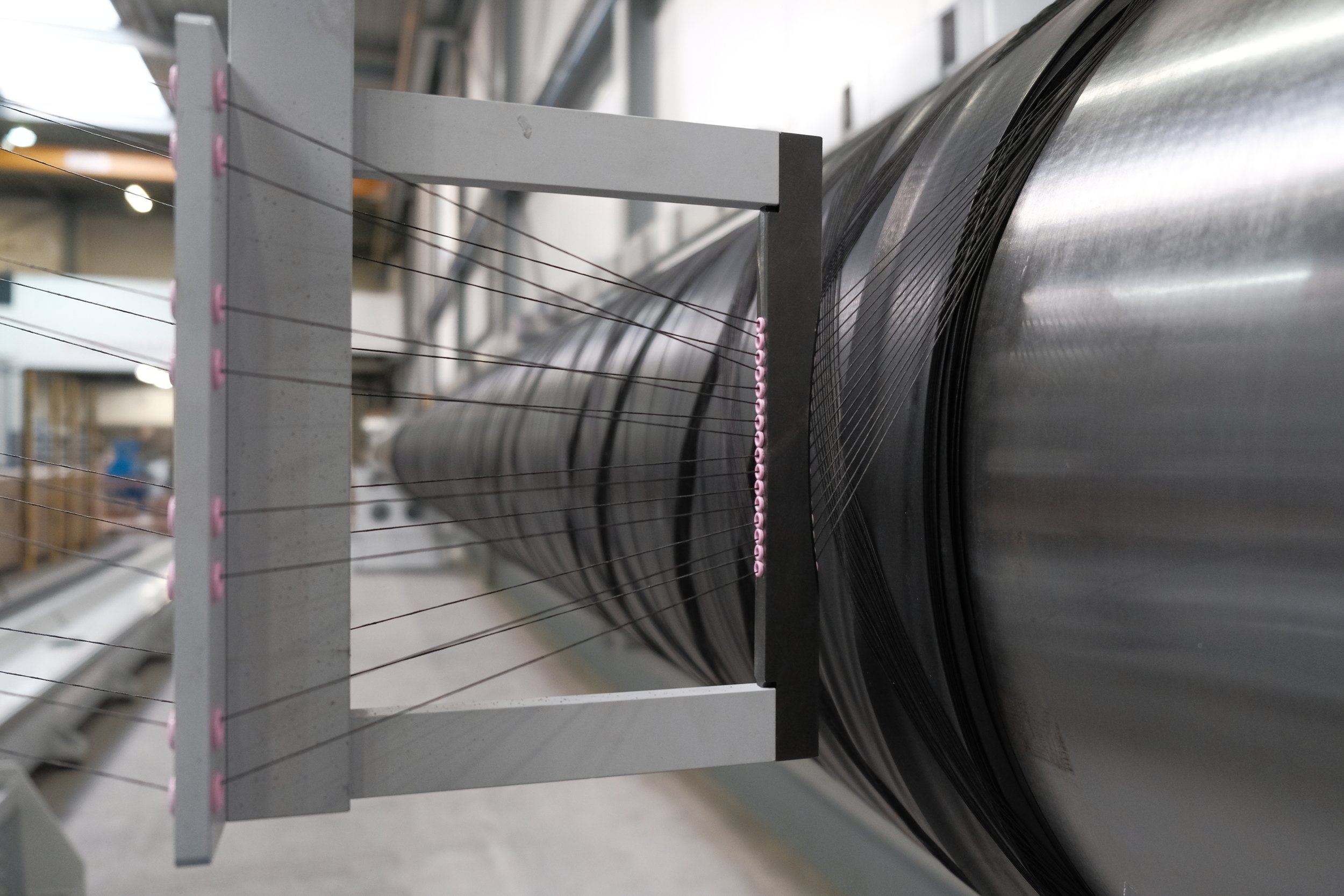

TANIQ uses various industrial robots to apply materials fast and accurately. Automated material winding is a different approach to conventional manual production. The materials themselves are not significantly different (the rubber compound and tape are the same). However, the physical form and process in wich the materials are supplied and placed is significantly different from manual production. Instead of frabic sheet, single cords are used. In stead of rubber sheets, rubber strips are used. And tape is supplied from a spool on the robot tool. These changes make robotic automated winding processes possibile.

Processes

Conventional production relies on rubberised reinforcement sheets, manually wrapped around a rotating mandrel. At the ends of the product the sheets are then slit and in some way connected to a coupling or other connection mechanism. For straight products this process could be reasonable fast, but especially for products with a double curvature (e.g. bellow) it is particularly difficult to place the sheets. Hence, conventional production typically relies on extensive experience and expertise to design and manufacture the products.

By replacing the reinforcement sheet by single cords (possibly rubberised), it is possible to apply the reinforcement material in a continuous manner – so from end to end without the need to slit the cords. This enables a continuous process, suitable for automation. Anchoring the reinforcement at the end of the product usually becomes obsolete or can be replaced with integrated couplings/flanges developed by TANIQ.

Like the reinforcement sheets, rubber is applied manually in the conventional process. Large sheets of rubber are wrapped around the rotating mandrel and gaps are manually filled. By slicing the rubber sheets and using long strips on a spool, the rubber can applied in a continuous manner – so from one end to the other end. This fast winding process ensures a consistent and repeatable layer that is applied with minimum chance of trapped air.

Tape placement is similar to manual application. The use of robotics, however, ensures constant, consistent and accurate tension. Hereby, the products looks are improved and consistent. More importantly, the product cures evenly and is identical to the design.

Material Winding

TANIQ's automation technology is based on separate winding of cord reinforcement, rubber strips and wrapping tape using end-effector tools. These tools enable fast, accurate and consistent placement of the material in a automated fashion. The robot has been designed to automatically pick-up and change tools with the help of multifunctional connectors. The tools:

Robotic Arms

Industrial robot arms have six degrees of freedom which enable manipulation of the material for accurate placement on the rotating mandrel. To apply different types of materials the robot can be fitted with different end-effectors dedicated for a specific job. For instance, placement of the fibres is achieved with a guiding tool at the end of the robot arm. The robot can switch the tools automatically, and thereby also automate rubber and tape application (which are applied manually in the conventional process). As a result, materials are continuously wound over the product, following the contours of the mandrel back and forth at high speed and automating the manual production processes. TANIQ has experience with multiple robot arm manufacturers: