Rubber-to-cord Adhesion Research

Research on rubber-to-cord adhesion

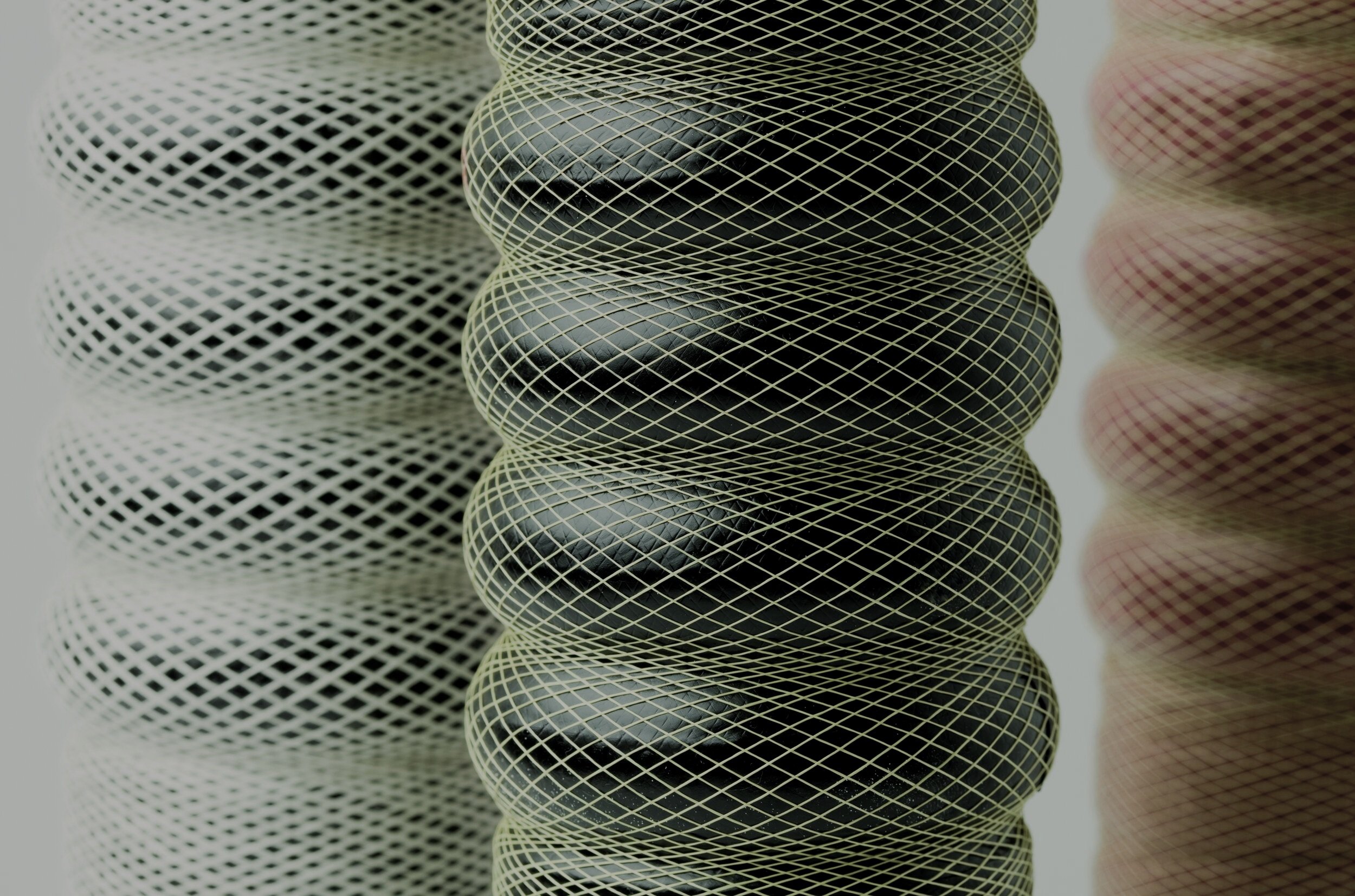

A good adhesion between rubber layers and reinforcement layers is benefical for the product perfomance during dynamic behavior. Different types of cords are used in reinforced rubber products such aramid, nylon and polyester. Each having their own advantages. The cords are treated with a special coating (e.g. RFL) to improve the adhesion between the cords and the rubber. TANIQ works closely together with Teijin Aramid and Milliken to develop the optimal cord construction and obtain maximum adhesion between the cords and rubber.

Peel-tests with various coatings and dippings

TANIQ has done extensive research on adhesion between cords with different coatings and dips, and rubber layers. Test have been executed using different types of cords, different winding angles, different cord coverage percentages and different coatings and dippings. As a result TANIQ has developed a formula for a cord coating that provides optimal rubber-to-cord adhesion in combination with the robotic cord winding process.

Dynamic tests for rubber-to-cord adhesion research

Besides peel tests TANIQ has run an intensive test program whereby TANIQ prototypes were tested on the testing facilities of Delft University of Technology (Zwick test bech) and on industrial testing equipment of TANIQ's customers. These dynamic test have lead to further optimizations of the product designs, and improvement of the cord coating itself. The prototypes were succesffully tested on axial and lateral movements up to more then 1 million cycles.

Abrasion resistance of cord reinforced polyurethane

Research to determine the influence of different reinforcement structures on the abrasion resistance of reinforced polyurethane products. Samples with different types of cords and steel wires embedded in polyurethane were developed and tested.